How To Clean Out A Sediment Trap Sink

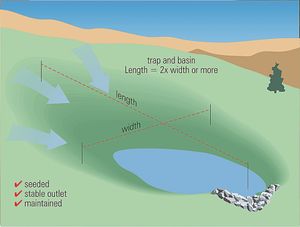

Temporary sediment trap with forebay, click image for more information (Source: Tetra Tech)

Sediment traps and basins are settling ponds formed by digging and/or an beach that intercept and retain sediment-laden runoff from a construction site for a sufficient period of fourth dimension to allow the majority of sediment to settle out prior to being released from the site. They may be constructed as smaller sediment traps – serving disturbed areas of less than five acres – or every bit larger sediment basins, handling mass grading runoff from subdivisions, commercial/institutional sites, or roadway projects. Proper use of these structures can greatly reduce sediment send off-site; if properly designed, installed, and maintained, sediment removal efficiency of 80 percentage or greater tin can be achieved, depending on soil particle size . Sediment traps are oftentimes temporary and usually decommissioned after the disturbed area is stabilized (i.east., with vegetation or other cover). Temporary sediment basins can exist converted to permanent stormwater management basins after construction is complete. Sediment traps and basins are very useful on structure sites with moderate to steep slopes . The selection of traps versus basins primarily depends on the size of the contributing drainage expanse and plans for post-construction stormwater management, as discussed below.

Contents

- 1 Purpose and function

- 2 Applicability

- two.1 Site applicability

- ii.two Permit applicability

- 2.2.1 Specific permit language

- 3 Effectiveness

- iv Planning Considerations

- five Design

- 5.i Sediment traps

- 5.2 Sediment Basins

- 6 Construction recommendations and specifications

- vii Inspection and maintenance

- 7.1 Sediment traps

- vii.2 Sediment Basins

- viii Costs

- nine Reference materials

- x Related pages

Purpose and function

Small sediment trap, click image for more information (Source: Georgia SWCC)

Sediment traps and basins function by intercepting and detaining site runoff, which allows soil particles to settle out prior to discharge. Sediment traps may serve several small catchments on a site, retaining runoff using embankments and other barriers and discharging through an armored overflow or piped outlet to a vegetated swale or other drainage feature. Sediment basins typically serve larger areas than sediment traps and may feature earthen embankments that retain runoff for longer periods of fourth dimension, releasing runoff via floating, perforated, or slotted risers or floating skimmers that depict antiseptic water from the surface

Applicability

Sediment traps and basins are very like in their siting, sizing, and design, with sediment traps serving areas of five acres or less and basins handling larger areas. They represent ane of the most effective and reliable measures for treating sediment-laden runoff from construction sites. These structures are typically placed nearly the perimeter of the site, where flows concentrate in swales , ditches, or other depression areas. Sediment traps and basins should exist constructed prior to disturbance of upslope areas, if possible, and keep performance until the contributing drainage area is fully stabilized. Specific considerations related to site applicability and permit applicability are discussed beneath.

Site applicability

Siting and pattern considerations for sediment traps/basins, click prototype for more than data (Source: Created by Tetra Tech for U.s. EPA and State of Kentucky)

Disturbed soils on a construction site have the potential to go out the site via stormwater runoff and negatively bear upon receiving water , roadways, and neighboring property. Sediment traps and basins should intercept full-bodied or sail flows of stormwater discharge from a construction site. Place sediment traps near the point of discharge and build traps in series to intercept and treat flow moving downwards long drainage paths through a site. Place stormwater basins in low lying areas on the outer edge of a structure site where water naturally flows or is directed according to site plans. Sediment traps are peculiarly useful in perimeter control areas where silt fences will probable fail. Do non site sediment traps in high-velocity catamenia areas (e.k., culvert outlets, steep ditches) where excessive turbulence and scour erosion may interfere with sediment settling processes. Neither practice should be placed in surface waters (including intermittent streams) or within their required buffer zones.

Permit applicability

Department 14 (Temporary Sediment Basins) of the MPCA Construction Stormwater Full general Permit (2018) has several requirements regarding sediment basins, including the following.

- Section 14.2: Temporary sediment basins are required where ten (ten) or more acres of disturbed soil drain to a common location. If the acreage of disturbed soil is reduced to less than ten (ten) acres due to establishment of permanent comprehend, the temporary basin is no longer required. Permittees may convert temporary sediment basins to permanent basins after completion of structure.

- Sections 14.iii and 14.4: For each acre of land that drains to the basin, the basin must provide sufficient live storage to concur runoff from a two-year 24-hour storm event or provide 1,800 cubic feet of live storage , whichever is greater. Where permittees have non calculated the ii (2)-twelvemonth, 24-hr storm runoff corporeality, the temporary basin must provide 3,600 cubic feet of live storage per acre of the basins' drainage area.

- Sections 14.5, 14.six, and 14.7: Outlet structures must preclude short-circuiting and belch of floating debris, withdraw water from the surface of the sediment pond, and have sufficient energy dissipation for the outlet within 24 hours after connecting to a surface h2o.

- Sections 14.eight and xiv.9: Temporary basins must be located exterior of surface waters and applicable buffer zones. Temporary basins must be constructed prior to disturbance of ten (ten) or more acres of soil draining to a common location.

- Department xiv.10 The general construction permit allows other effective sediment controls (e.g., a series of smaller sediment basins and/or sediment traps, silt fences, vegetative buffer strips, etc.) if sediment basin requirements are infeasible to meet on a particular site. This determination must be documented in the SWPPP (Stormwater Pollution Prevention Plan).

Specific permit language

Applicability

- Specifically, section 14.2 of the MPCA Construction Stormwater Full general Let (2018) states: "Where ten (10) or more acres of disturbed soil drain to a common location, permittees must provide a temporary sediment basin to provide treatment of the runoff earlier information technology leaves the construction site or enters surface waters. Permittees may convert a temporary sediment basin to a permanent basin after construction is complete. The temporary basin is no longer required when permanent encompass has reduced the acreage of disturbed soil to less than ten (10) acres draining to a common location. "

Sizing

- Department 14.three states: "The temporary basin must provide live storage for a calculated volume of runoff from a two (two)-year, 24-hour tempest from each acre drained to the basin or one,800 cubic anxiety of live storage per acre drained, whichever is greater."

- Section fourteen.iv states: "Where permittees accept not calculated the two (ii)-year, 24-hour tempest runoff amount, the temporary basin must provide 3,600 cubic anxiety of live storage per acre of the basins' drainage surface area".

Outlets

- Section 14.5 states: "Permittees must blueprint basin outlets to prevent short-circuiting and the discharge of floating debris."

- Section 14.half-dozen states: "Permittees must design the outlet structure to withdraw water from the surface to minimize the discharge of pollutants. Permittees may temporarily suspend the apply of a surface withdrawal mechanism during frozen conditions. The bowl must include a stabilized emergency overflow to prevent failure of swimming integrity."

- Section 14.vii states: "Permittees must provide energy dissipation for the basin outlet within 24 hours subsequently connection to a surface water."

Location and timing

- Section xiv.8 states:"Permittees must locate temporary basins outside of surface waters and any buffer zone required in item 23.11 of the general permit."

- Section 14.nine states: "Permittees must construct the temporary basins prior to disturbing 10 or more acres of soil draining to a common location."

Alternatives

- Department 14.x states: "Where a temporary sediment basin meeting the requirements of item 14.iii through 14.9 is infeasible, permittees must install effective sediment controls such every bit smaller sediment basins and/or sediment traps, silt fences, vegetative buffer strips or any appropriate combination of measures as dictated by individual site conditions. In determining whether installing a sediment bowl is infeasible, permittees must consider public safety and may consider factors such as site soils, slope, and available area on-site. Permittees must document this determination of infeasibility in the SWPPP".

Additional information on basin drainage is provided in Construction stormwater treatment - dewatering.

Effectiveness

When designed, installed, and maintained properly, sediment traps and basins have sediment-trapping efficiencies typically betwixt sixty and lxxx percent. They need little maintenance compared to other practices that treat sediment-laden runoff, provided upland areas are brought to final class and stabilized promptly. Sediment traps and basins provide skillful command of coarse sediment and are moderately effective for trapping medium-size sediment particles. Withal, they have a relatively low trapping efficiency for fine silt and clay particles suspended in runoff. Longer detention times, use of a flocculant (e.g., floc log contact with upstream incoming flows), or additional sediment control measures may be necessary for removal of finer-textured sediment. In full general, the larger the storage volume and the longer the detention time of the stormwater, the more efficient sediment basins are at removing finer particles. Oil, grease, and other floatables may also be removed if using an outlet piping that features perforated openings, a screen, a skimmer, or other ways to draw ponded water from just beneath the surface. Effectiveness in removing floatables is dependent on the outlet blueprint. Every bit a secondary design benefit, sediment traps and basins tin can also help control the menstruation rate and potentially the volume of runoff from a site.

Expected performance for temporary/permanent sediment traps and basins.

Link to this table

| H2o quantity | |

|---|---|

| Flow attenuation | Secondary design benefit |

| Runoff book reduction | Secondary design benefit |

| Water quality | |

| Erosion prevention | Little or no design do good |

| Sediment control | Primary design do good |

| Nutrient loading | Secondary design benefit |

| Pollutant removal | |

| Full suspended solids | Primary design benefit |

| Total phosphorus | Secondary blueprint benefit |

| Heavy metals | Secondary design benefit |

| Floatables | Secondary design benefit |

| Oil and grease | Secondary pattern benefit |

Planning Considerations

Where to install sediment traps/basins, click paradigm for more data (Source: Tetra Tech)

Permanent stormwater bowl, click paradigm for more data (Source: Tetra Tech)

Sediment bowl with baffles, click prototype for more data (Source: Tetra Tech)

Sediment Traps

In order to successfully prevent off-site migration of sediment, sediment traps need to exist properly functioning and in the correct location on site. They should be installed early on in the project earlier the site clearing phase begins. The natural drainage of a construction site should be considered prior to planning sediment trap size and location. Locate areas of potential sediment runoff, decide the likely pathway for water draining from those sites, and place sediment traps between the source of sediment and the site perimeter or h2o body that will receive the runoff. For maximum effectiveness, sediment traps should be placed every bit close as possible to the source of sediment runoff. If the site configuration prevents the use of a single sediment trap, multiple smaller traps bundled in series can be used to see the design requirement.

Sediment Basins

If sediment traps are not sufficient for stormwater and sediment control, apply sediment basins due to their larger chapters. Basins have a larger footprint than sediment traps and should be sited at a low point on the structure site, where runoff converges. If stormwater does not naturally flow towards the sediment basin and cannot feasibly exist directed to information technology, a series of sediment traps or other BMPs may be more appropriate for sediment control. It is recommended that the slopes that comport runoff to the basin be greater than ane per centum but no more than 25 percent to promote menstruum towards the bowl. Similar to sediment traps, install sediment basins prior to soil disturbing activities wherever possible. When selecting an surface area to place a sediment basin, look for areas that meet the following recommendations.

- Capable of storing sediment and stormwater from as much of the planned disturbed area as applied

- Provide access for maintenance throughout the project

- Are far enough away (minimum of 20 feet of separation) from existing building foundations to preserve their integrity

- Where groundwater levels will be lower than the basin bottom

- Limit handling to runoff from disturbed areas only

- Minimally interfere with the construction site

Temporary sediment basins are often converted to permanent stormwater management structures once all disturbed contributory drainage areas take been permanently stabilized and canonical by a stormwater inspection entity and all storm drains accept been flushed. The outlet structure must be installed in accord with an canonical stormwater management pattern plan. Additional grading may be necessary to achieve the required storage volume of the basin. Prior to transition to a post-construction stormwater basin, the basin must be cleared of accumulated sediment, fully stabilized, and inspected to ensure that side slopes and the volume, containment berm, outlet, and inlets comply with stormwater bowl design requirements. Link here for design data for permanent stormwater ponds.

Design

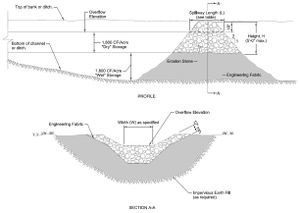

Typical sediment trap pattern, click image to enlarge (Source: Iowa SUDAS, 2022)

Designs for traps and basins should specify a minimum length to width ratio of ii:1 if possible. The surface area of a sediment trap or basin may range from approximately 4 to ten percent or more of the area draining to them, depending on their shape, depth, incoming soil particle size, use of flocculants, and other factors. In general, longer flow paths through the trap/bowl and greater detention times results in higher rates of sediment removal via settling processes.

Sediment traps

A temporary sediment trap should only be used in a location with a drainage area of five (5) acres or less and where it will be used for two years or less.

Sediment traps must take an outlet to conduct runoff from the construction. The outlet tin be a pipe outlet, stabilized rock outlet, or other suitable construction. The outlet must be capable of handling the runoff from a 2-year-frequency, 24-hour-duration tempest without failure or significant erosion. Overflow outlets should be stabilized with coarse aggregate and/or riprap and geotextile fabric. For more information on outlet stabilization, link here.

Sediment trap sizing is dependent on the anticipated drainage area and book of stormwater to treat. A side gradient ratio of 2:1 or flatter is recommended for sediment traps. A minimum length to width ratio of 2:ane should be provided, and the distance between the inlet and outlet should exist maximized to increase sediment removal efficiency. Where flow paths are shortened due to tight site conditions, silt fencing can exist used as baffles inside the trap to ho-hum flows through the trap and increase sediment removal.

The example blueprint table below provides general guidance on sizing rectangular sediment traps with sloped sides, based on contributing drainage area. Volumes for sediment traps constructed by installing a rock berm or earthen embankment across a swale can be estimated using the triangular pyramid volume formula. As a dominion of thumb, a total storage book of 3,600 ft3 should be provided for every acre of contributing drainage. This volume may be as divided betwixt wet (retention) and dry (drawdown, or dewatered) storage. Wet storage is provided in a permanent pool and dry storage provides extended settling time.

Sediment trap sizing tabular array

Link to this table

| Drainage area (ac) | Total Volume (ft3) | Wet Volume (ft3) | Dry Volume (ft3) | Minimum Depth (ft) | Depth of Permanent Pool (ft) | Minimum Bottom Length (ft) | Minimum Lesser Width |

|---|---|---|---|---|---|---|---|

| 1 | 3600 | 1800 | 1800 | two.5 | i.v | 46 | 23 |

| 2 | 7200 | 3600 | 3600 | 2.75 | 1.five | 64 | 32 |

| 3 | 10800 | 5400 | 5400 | three.0 | 1.75 | 76 | 38 |

Table assumes 2:1 side slopes; Minimum depth is from trap bottom to weir crest and includes both moisture and dry storage

Embankments are located at the lowest point of the sediment trap and typically consist of mixed size rock or a stabilized earthen berm with a rock-armored overflow notch. The bottom of the beach should exist level with the moisture storage portion of the trap. The design table beneath summarizes the recommended beach meridian width (also referred to equally weir length) for sediment traps as a part of contributing drainage area.

Recommended beach widths for sediment traps

Link to this table

| Contributing Drainage Area (acre) | Beach Width (ft) |

|---|---|

| one | 4 |

| 2 | 6 |

| 3 | eight |

| four | 10 |

| five | 12 |

Sediment Basins

Per the 2022 MPCA Construction Stormwater Full general Allow, sediment basins are required when 10 (10) or more acres of disturbed land discharges to a common location. If the site is located within one mile of a special or impaired water , sediment basins are required when five (5) or more acres of disturbed state discharges to a common location. The maximum drainage area for a unmarried sediment basin should not exceed 100 acres.

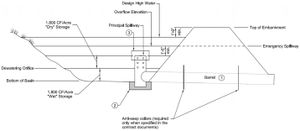

Sediment basins consist of a principal spillway, dewatering device, and an emergency (overflow) spillway. A principal spillway conveys the design volume of treated stormwater abroad from the site and discharges it. It consists of a vertical riser that controls basin water levels and an outlet pipe. A dewatering device releases the runoff over time, assuasive the sediment to settle out. Dewatering devices can take many forms including modifications to risers and floating skimmers. The MPCA Construction Stormwater Full general Permit (Section 14.6) requires emergency spillways to safely pass stormwater from storms exceeding the basin design storm without compromising the integrity of the basin.

The total storage volume provided past sediment basins should be a minimum of 3,600 cubic feet per acre of contributing area. Contributing drainage area should include the entire drainage area, not only the disturbed surface area. The full storage volume should be divided equally between wet (memory) and dry (drawdown, or dewatered) storage. Storage book is measured from the bottom of the basin to the elevation of the main spillway crest.

Typical design for a sediment bowl with an emergency spillway, click image to overstate (Source: Iowa SUDAS, 2022)

Floating skimmer installed in temporary sediment basin to describe and belch cleaner water from the height of the impoundment. (Source: J. Due west. Faircloth & Son, Inc.)

The following design recommendations apply to sediment basins:

- The ratio of the surface expanse (ft2) at the designed high h2o elevation to the discharge rate from a 15-twelvemonth, 24-60 minutes storm (cfs) is greater than or equal to 0.0035.

- Bowl length to width ratio should be 2:one or greater , in order to maximize settling time.

- Use a wedge design with the inlet located at the narrow end of the bowl.

- Locate inflows to the basin as far from the riser every bit possible to maximize travel fourth dimension through the basin and increase effectiveness of handling. Baffles may be installed to maximize detention time and increase sediment removal efficiency.

- For small-scale temporary sediment traps, the embankment height should not exceed 5 anxiety. For temporary sediment basins, the beach (dam) superlative should non exceed fifteen (15) feet.

- For embankments up to x (10) feet in height, the beach top width should exist a minimum of eight (8) feet. For embankments between 10 (10) and 15 (fifteen) feet in tiptop, the minimum top width should be 10 (10) feet.

- Soils used for embankments exceeding five feet must be selected and compacted in accordance with NRCS or MnDOT standards.

- For rock sediment trap berms, utilize mixed size stone to ensure slower drain-downwards times and maximum sediment settling.

- Design inside beach side slopes at a ratio of 2:1 or flatter, and outside beach side slopes 3:ane or flatter. Design all slopes to exist stable through the use of erosion controls such equally seeding, mulching, and sodding.

- Protect inflows and outlets from erosion past armoring with riprap or other appropriate techniques.

- Increment detention time by using rock, filter fabric, rock bags, or like measures to modify the inlet, and use berms or other approaches that tedious down exiting catamenia to allow more sediment to settle.

- Increase sediment removal via flocculation and faster settling through the use of polymers , available as powders, flocculant logs/bags, and other products. Follow manufacturer's directions for applicability and use. For more information see Construction stormwater treatment - dewatering, including chemical handling and sediment filtration.

- For superior sediment bowl discharge water quality, consider use of a floating skimmer. These devices draw antiseptic water from the surface of the impounded stormwater, where sediment concentrations are the lowest. Several do-information technology-yourself and proprietary products are bachelor to cull from; see here for more information.

Structure recommendations and specifications

While sediment traps differ from basins in design options, sizing, and (typically) permanence, there are some basic structure recommendations common to both BMPs:

- Install traps/basins prior to disturbing large portions of the upland structure site, so they are available for sediment removal during the agile construction period.

- Assess drainage toward the trap/bowl to ensure it conforms to site design. Use berms or ditches to capture flows that may featherbed the trap/basin where necessary.

- Clear and grub the area under the beach, removing any vegetation and the root mat.

- Ensure that earthen containment berms are constructed according to design. Soils used to construct the embankment must be gratuitous of roots, woody debris, large rock, organic cloth, and other non-soil material.

- Compact containment embankment make full soils by traversing with equipment in one-human foot lifts during construction..

- Ensure that the berm is capable of treatment the lateral stress from ponded water (i.e., apply MnDOT and NRCS soil and compaction specifications for embankments exceeding five feet in pinnacle).

- For rock sediment trap berms, use mixed size rock to ensure slower drain-downwardly times and maximum sediment settling.

- Outlets (eastward.g., overflow, piped) must be stable and able to handle heavy incoming/approachable flows.

- Ensure there are no large bottom-height outlet construction holes, pipe openings, stone voids in the berm, or other features that may cause the trap/basin to bleed downward less than 12 to 24 hours after a rain.

- Mixed size rock berms or filter fabric can be used, if necessary, to wearisome flows from permanent stormwater outlets during the structure menstruation.

- Remove limbs, droppings, trash, building materials, soil stockpiles, etc. immediately subsequently constructing the trap/basin.

- Stabilize side slopes and berms of traps/basins with seed, erosion control blanket, rock, etc. every bit soon as they are congenital, to prevent filling the available volume with sediment from the trap/basin itself. The lesser can remain unstabilized until final sediment removal occurs.

- Ensure that stormwater discharges from the basin will go out onto an armored anti-scour pad or other erosion proof construction/surface area, and can move downstream via stabilized swales, ditches, channels, or every bit canvass period.

- Remove any not-sediment upland materials that may wash into the trap/basin (eastward.g., limbs, debris, trash, edifice materials, etc.)

- Stabilize upland areas that may contribute significant amounts of eroded soil to the trap/basin as chop-chop as possible, to avoid frequent dredging and maintenance.

- Use silt fencing or other sediment controls where necessary to further reduce sediment inputs to the trap/basin – it is easier to remove sediment from a silt fence than a trap/basin.

The 2022 MnDOT Standard Specifications for Construction includes several specifications relevant to sediment basins and traps.

- MnDOT Specification 2573.three Part A includes guidance for construction of temporary sediment basins and traps. Part A.4 (folio 514) states: "Construct temporary sediment basins concurrently with the start of soil disturbing activities. Straight storm water runoff from drainage areas to the basins. Stabilize the exposed side slopes of the basins. Provide an outlet to the basin that discharges water from the surface, separates floatables, and provides scour protection or energy dissipation." Part A.half-dozen requires the use of a water handling programme for these devices, stating: "Provide a h2o treatment program for turbid or sediment laden water. Submit the water handling programme to the Engineer before pumping. Do not begin work until the Engineer accepts the water treatment plan including any contractor required permits. Include in the water treatment program the employ of sediment traps, vegetative filter strips, flocculants, or other water treatments per 3875, 'Water Treatments'."

- MnDOT Specification 2573.3 Office P includes guidance for the maintenance of sediment basins and traps. Part P.ii (page 518) states: "Bleed the bowl and remove the sediment when the depth of sediment collected in the basin reaches 50 pct of the storage volume determined past the outfall device. Complete drainage and removal within 72 hours or as soon every bit field conditions permit access. Remove sediment to the original designed or excavated grade or as necessary to restore the function of the device. Restore stabilized condition of side slopes and access route. Clean out and shape temporary sedimentation basins intended for utilise equally permanent water quality management basins as shown on the plans." Maintenance is discussed in greater item below.

- MnDOT Specification 2573.4 prescribes "method of measurement" related to temporary sediment traps and basins. Part E (Temporary Sediment Traps, folio 519) states: "The Engineer volition measure sediment trap digging by volume. The Engineer will measure out overflow devices separately." Further, Role One thousand (Sediment Removal) states: "The Engineer will mensurate sediment removal from temporary sediment traps and basins by backhoe hours or vac-truck hours. The spreading and hauling of sediment is incidental to the backhoe hour removal."

- MnDOT Specification 2573.5 prescribes "ground of payment" related to temporary sediment traps and basins. Function Yard (Sediment Traps, page 520) states: "The Department will pay for removal of sediment from sediment traps by backhoe or vac-truck 60 minutes. Sediment spreading and disposal are incidental." Farther, Office I (Pay Items, page 521) states that payment past the Department for sediment trap digging (Item No. 2573.504) shall be calculated on the basis of cubic yards.

- MnDOT Specification 3875 (Water Treatment) outlines requirements for utilize of passive dewatering treatment methods for sediment traps and basins. Specification 3875.ii Part A (page 694) states: "Use passive dewatering treatment methods, using time and gravity to settle out sediments, if draining basins, traps, ditches, or sumps to prepare the construction site for the adjacent storm event." Office A.2 provides specifications regarding the design of the riser piping, stating: "Provide a riser pipe in a swimming, bowl, or trap outlet structure meeting the following requirements or characteristics.

- Ii-thirds the height of the outlet higher up the floor of the structure

- Fabricated of perforated PVC or metal pipe of the aforementioned diameter as the outlet structure

- Surrounded by make clean rock from 1 in to two in, for the unabridged height of the riser pipe.

- Install a trash guard on the top overflow."

The relevant specifications noted above in 2573.4 (Method of Measurement) and 2573.five (Basis of Payment) are of import when considering cost implications of these practices, discussed further below.

Inspection and maintenance

Neglected temporary sediment trap, click prototype for more than information (Source: Tetra Tech)

Sediment traps

The MPCA Construction Stormwater General Permit does not include specific requirements for inspection and maintenance of temporary sediment traps. Temporary sediment traps, withal, should be inspected at least weekly and after each 0.five-inch or greater rainfall event and repaired immediately. Recommended maintenance includes the following.

- Ensure that trap sidewalls are vegetated or otherwise stabilized to forestall erosion of the structure and filling of the trap book.

- Check spillway for accumulated debris, erosion, and displacement of rock.

- Immediately address erosion, bulging, or other conditions indicating weakness or potential failure of the containment berm.

- Remove sediment from the trap when sediment accumulates to the clean out level (50 percentage of moisture storage depth).

Dispose of dredged sediment at fill up areas, soil stockpiles, or other locations where it can be stabilized with vegetation or contained via sediment controls (e.g., silt fencing). Dredged sediment containing hazardous wastes (i.due east., from demolition debris, waste sites, etc.) must be characterized and disposed of in accordance with MPCA requirements.

- When performing sediment cleanout, inspect the trap for accumulated trash and other debris. Keep inflow, outflow, and interior of trap articulate of any droppings.

- Forestall erosion at inflow and outflow by installing and maintaining riprap or other appropriate measures.

- Stabilize or use silt fencing to address upslope areas that are contributing excessive volumes of sediment to the trap and increasing maintenance needs.

- Maintain original dimensions of trap (class, depth, etc.) throughout life of practice.

Sediment Basins

The recommended maintenance activities outlined above for sediment traps besides employ to sediment basins. Maintenance of sediment basins is necessary when sediment levels accomplish half of the design volume of the basin. Once this threshold is reached, 72 hours are allotted for proper maintenance to occur. As noted above, MnDOT Specification 2573.3 Part P.2 states: "Bleed the basin and remove the sediment when the depth of sediment collected in the basin reaches 50 percent of the storage book determined by the outfall device. Consummate drainage and removal within 72 hours or equally before long as field atmospheric condition allow admission. Remove sediment to the original designed or excavated grade or equally necessary to restore the function of the device. Restore stabilized condition of side slopes and access road. Clean out and shape temporary sedimentation basins intended for utilize every bit permanent water quality management basins as shown on the plans."

Additionally, during inspections, evaluate the embankment for signs of seepage, settlement, or slumping. Whatsoever issues should be repaired immediately. All woody vegetation (e.g., trees, brush, etc.) should exist cleared from the embankment and principal spillway. During sediment cleanout, trash and other droppings should be removed from the basin, dewatering device, and riser structure.

Costs

The following table summarizes estimated BMP costs based on MnDOT data summarizing average bid prices for awarded projects in 2022.

Unit costs related to sediment traps and basins

Link to this table

| Bid item | Detail clarification | Units | Average price |

|---|---|---|---|

| 2573602/00010 | Temporary sediment trap | each | $605.00 |

| 2106501/00010 | Excavation – common | cubic yards | $v.60 |

| 2106607/00020 | Digging – subgrade | cubic yards | $nine.59 |

| 2106523/00060 | Common embankment (CV) | cubic yards | $2.eighteen |

| 2106521/00070 | Granular embankment (CV) | cubic yards | $8.51 |

Reference materials

Except where more stringent recommendations are presented in this guidance, BMPs shall comply with MnDOT and other state requirements. Chief pattern references include:

- 2018 Minnesota NPDES/SDS Construction Stormwater General Permit

- MnDOT Standard Specifications for Construction

- Minnesota Urban Small Sites All-time Management Practise Manual (Chapter 3: Runoff Pollution Prevention – Temporary Sedimentation Basins/Traps)

- MnDOT Erosion Control Handbook II

The post-obit is a list of additional resources that are not specific to Minnesota:

- Make clean Water Services Erosion Prevention and Sediment Control Transmission (2008) (4.3.9 Sediment Basin and 4.three.11 Sediment Trap)

- Contractor's Handbook for Erosion, Sediment, and Stormwater Management on Majuscule Project Construction Sites (Lexington-Fayette Urban County Regime) (2018)

- District of Columbia Erosion and Sediment Control Manual (2017) (Chapter 6)

- Iowa Statewide Urban Design and Specification (SUDAS) Design Manual (2016) (Capacity 7E-12 and 7E-13)

- Kentucky Erosion Prevention and Sediment Command Manual (Revised 2009). (Chapter 4.7)

- New York State Standards and Specifications for Erosion and Sediment Control (2016)

- Stabilization practices

- Erosion prevention practices

- Erosion prevention practices - temporary seeding and stabilization

- Erosion prevention practices - natural and constructed mulches

- Erosion prevention practices - tackifiers and soil stabilizers

- Erosion prevention practices - erosion control blankets and anchoring devices

- Erosion prevention practices - turf reinforcement mats

- Erosion prevention practices - Riprap

- Sediment control practices

- Sediment command practices - Vehicle tracking BMPs

- Sediment control practices - Perimeter controls for disturbed areas

- Sediment command practices - Check dams (ditch checks, ditch dikes)

- Sediment control practices - Diversion barrier controls (cofferdams/temporary dikes)

- Sediment control practices - Storm drain inlet protection

- Sediment control practices - Outlet energy dissipation

- Sediment command practices - Sediment traps and basins

- Sediment command practices - Stabilized world/soil berm

- Construction stormwater treatment - dewatering, including chemical handling and sediment filtration

- Construction stormwater best management exercise – buffer zones

- Other practices

- Construction stormwater practices - temporary stream crossing

- Construction stormwater practices - diversion and working in the dry

- Construction stormwater treatment - BMP removal after last stabilization

- General principles for erosion prevention and sediment control at construction sites in Minnesota

- Construction stormwater photo gallery

Source: https://stormwater.pca.state.mn.us/index.php?title=Sediment_control_practices_-_Sediment_traps_and_basins

Posted by: mccallshavers.blogspot.com

0 Response to "How To Clean Out A Sediment Trap Sink"

Post a Comment